broyeur de pierres épaisseur 60 cm - blitzcontainer

Largeur de coupe: 1,35, 1,55, 1,7, 0,95, 1,15 m Vitesse de rotation: 1 000, 540 rpm Puissance tracteur: 10 ch - 40 ch. FURBA est un broyeur autoporté pour le broyage de l'herbe et

Consulter un spécialiste

Broyeur hydraulique pour mini-pelle de 60cm

Conçu spécialement pour têtes de broyage Deleks. Monodirectionnel à 2 tubes (ne nécessite pas le troisième tube de drainage). Équipé d’un roulement de soutien sur l’arbre. Joint d’huile renforcé. Valve de pression maximale

Consulter un spécialiste

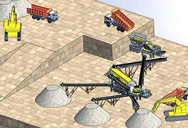

STCM - Broyeur de pierres - FAE

Broyeur de pierres pour tracteurs d'une puissance de 80 à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres

Consulter un spécialiste

Broyeur de pierres - Tous les fabricants industriels

Trouvez facilement votre broyeur de pierres parmi les 60 références des plus grandes marques (Eriez, Liming, NEUE HERBOLD, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos

Consulter un spécialiste

Enfouisseur de pierres - Tous les fabricants de

Puissance tracteur: 20 ch - 60 ch. Cette enfouisseur de pierres est idéal pour enfouir les pierres, les mottes de terre et la végétation de surface, avant de semer sous serre et dans les jardins. Une grille spéciale permet ...

Consulter un spécialiste

MIDIPIERRE - broyeur de pierres 80-130 CV SEPPI M.

2 天之前 Le petite broyeur de pierres MIDIPIERRE élimine les pierres du terrain, en les broyant. Cela est utile pour les terrains agricoles, pour les jachères, pour entretenir pistes de ski ou

Consulter un spécialiste

Broyeur Électrique Hyundai 2500 Watts - Brico

Caractéristiques principales : Numéro de modèle : 57388. EAN : 8718502573886. Tension d'alimentation : 230-240 V, 50 Hz. Puissance : 2500 W. Vitesse maximale des lames : 60

Consulter un spécialiste

broyeur de pierre epaisseur 60 cm - amc-fuzy

broyeur pierre et cailloux - Zenith-concasseur,broyeur2018年7月9日 Concasseur à mâchoires et concasseur à cône sont fréquents en utilisant un broyeur pierre et cailloux. Le cailloux est une sorte de pierre naturelle, ses principales [randpi ... broyeur de pierre epaisseur 60 cm POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION ...Consulter un spécialiste

broyeur pierre et cailloux - Zenith-concasseur,broyeur2018年7月9日 Concasseur à mâchoires et concasseur à cône sont fréquents en utilisant un broyeur pierre et cailloux. Le cailloux est une sorte de pierre naturelle, ses principales [randpi ... broyeur de pierre epaisseur 60 cm POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION ...Consulter un spécialiste

Broyeur hydraulique pour mini-pelle de 60cm

Broyeur hydraulique de 60cm pour mini-pelles 1,0-2,0 tonnes - DELEKS - Made in Italy - 2 ans de garantie ... Made in Italy - 2 ans de garantie Broyeur DELEKS ® ARS-60 pour mini pelles 1,0-2,0 tonnes. Débroussailleuse hydraulique pour

Consulter un spécialiste

Isolation murs 60 cm épaisseur - Bricoleur du Dimanche

2009年12月20日 J'ai maintenant une maison en pierre, même épaisseur de mur extérieur, ils sont doublés avec un vide d'air avec du placo et 4 cm de polyuréthane fixé sur armature. Mon erreur, j'ai mis une brique à l'intérieur sur les autres murs.

Consulter un spécialiste

Faut-il isoler un mur en pierre de 50 cm - Mieux Rénover

2022年10月5日 Isoler un mur en pierre de 50 cm Comment isoler un mur de 50 cm par l’intérieur ? Pour isoler un mur en pierre de 50cm par l’intérieur, l’isolant devra avoir une épaisseur d’au moins 5 cm et être à 2cm de chaque paroi du mur en pierre.Cette lame d’air est importante car, en évitant le contact direct avec l’humidité, cela empêche l’accumulation de l’air dans les murs ...

Consulter un spécialiste

isoler un mur en pierre : pourquoi et comment faire

Une maison ancienne possède traditionnellement des murs épais de 50 à 60 cm (parfois jusqu’à 1 m). L’inertie importante de ces murs en pierre épais va retarder l’entrée du froid ou de la chaleur à l’intérieur des pièces. ... Nous avons acheter une maison en pierre de Caen ayant des murs extérieurs de 70Cm d'épaisseur ...

Consulter un spécialiste

percer un mur en pierre de 65cm d'épaisseur - Bricoleur du

2007年12月12日 Bonjour Gregorias et bienvenue sur ce forum Quand au choix du matériel, il y a 2 facteurs qui pour moi rentrent en jeu : - si ton mur est en pierre de taille ou en pierre assemblée avec un liant - Ton expérience à magner des outils relativement puissant. Si ton mur est en pierre de taille une carotteuse louée chez un spécialiste de la location de matériels

Consulter un spécialiste

Palette 96 Blocs de béton cellulaire 60 x 25 x 10 cm

C'est le matériau de base utilisé pour la construction de bâtiment, en particulier de maisons individuelles. Ce bloc est lissé et doit être collé horizontalement ou verticalement. Il a une longueur de 60 cm, une hauteur de 25 cm et une épaisseur de 10 cm. Un bloc de béton cellulaire est fabriqué avec les composants suivants : Quartz ...

Consulter un spécialiste

Broyeur de branches, broyeur de végétaux 7 CV 208 cc - Max

Broyeur de branches: Pierre R. le 04/10/2020: Bon produit, bien emballé, facile a monté.broyeur idéal pour des branches de 2 ,3 Cm de diamètre Il se bouche à la sortie si les branches sont vertes et avec des feuilles. ... BROYEUR DE BRANCHES 7 CV - MAXI 60 MM: Jean-Pierre D. le 22/08/2019: ... SUPER BROYEUR POUR LES BRANCHES DE 10 CM ...

Consulter un spécialiste

Grès cérame Mirage Motley liverpool 06 structuré épaisseur 20 mm 60

Grès cérame Mirage Motley liverpool 06 structuré épaisseur 20 mm 60 x 120 cm BGT2 de la marque MIRAGE sur Pointp. Retrait en agence sous 2h. 850 Agences et 150 Showrooms. Paiement sécurisé.

Consulter un spécialiste

Dalle pierre de luzerne 60 x 30 cm, ép.2/4 cm - Castorama

Dalle pierre de luzerne 60 x 30 cm, ép.2/4 cm Voir articles similaires. Dalle pierre de luzerne 60 x 30 cm, ép.2/4 cm. Vendu et expédié par Castorama. 9 € soit 50 € ... Dimensions : L. 60 x 30 cm; Épaisseur : 2/4 cm; Teinté dans la masse; Nombre par m² : 6; Poids au m² : 80 kg; Spécifications techniques. Type d'article: Dalle:

Consulter un spécialiste

Calculateur de poids de granit Estimez le poids de votre pierre

2023年5月5日 Un calculateur de poids de granit est un outil numérique qui calcule le poids du granit en fonction de ses dimensions (longueur, largeur et épaisseur). En saisissant ces des mesures dans la calculatrice, vous pouvez déterminer le poids total du granit, ce qui facilite la planification et l'exécution efficace de votre projet.

Consulter un spécialiste

TS Industrie broyeur de bois WS18-35DT /

Broyeur de bois WS18DT – pour branches jusqu’à diamètre 18 cm. Moteur diesel Kubota de 25 CV à demarreur électrique. Système Cutting Disc: volant de 74 cm de diamètre avec 2 lames réglables.; Avec système No Stress: régle de façon

Consulter un spécialiste

Epaisseur dallage pierre. Quelle épaisseur pour

La pose collée en intérieur ou en terrasse/allée piétonne – Epaisseur de 1,5 ou 2 cm. La pierre de Bourgogne est fabriquée au minimum en 1,5 cm d’épais ; en fonction du type de pierre, de la taille des dalles et de vos contraintes

Consulter un spécialiste

[Test, avis et prix] Broyeur de végétaux Forest Master FM4DDE

2024年5月3日 Si vous recherchez un modèle abordable ou compact, pensez au broyeur électrique Einhell GC-RS 60 CB ou au broyeur électrique Gardebruk 2400W. ... Épaisseur de branche max. 5 cm: Système de broyage: A disque porte-lames: Diamètre des roues: 250 mm: À propos de l’auteur : Quentin, jardinier passionné

Consulter un spécialiste

Plaquette de parement mural pierre reconstituée - Manoir - ton Pierre ...

Parez vos murs avec ce parement mural de la collection Manoir et offrez à votre bâtisse un style authentique et chaleureux à faire pâlir les belles maisons de campagne.. Ce parement mural est en pierre reconstituée de faible épaisseur (± 2 cm), avec un aspect du moellon calcaire, des reliefs marqués et irréguliers pour obtenir un rendu naturel sur tous les murs intérieurs ou ...

Consulter un spécialiste

EINHELL -GC-RS 60 CB Broyeur de Végétaux -220V

EINHELL -GC-RS 60 CB Broyeur de Végétaux -220V -

Consulter un spécialiste

La cuisine est l’une des pièces les plus difficiles à aménager

4 • Laisser une largeur de passage suffisante : afin d’ouvrir facilement portes et tiroirs d’un élément bas (60 cm de profondeur) vous devez disposer d’un espace d’au moins 90 cm devant le meuble ou si vous souhaitez qu’une autre personne circule pendant que vous travaillez devant le plan de travail il faudra alors 140 cm. Pour ouvrir un four, il faut un espace d’au moins un ...

Consulter un spécialiste

Le broyeur scheppach-Test et avis complet 2024 - Mes

Que vaut le broyeur scheppach en 2024 ?Points forts,caractéristiques,conseils du broyeur de végétaux électrique scheppach gs60 2800w. ... Lors de nos tests, le broyeur scheppach gs 60 a broyé des branches et des feuilles jusqu’à 30 mm d’épaisseur. ... Cela permet à l’utilisateur d’ajuster l’épaisseur de la coupe en fonction ...

Consulter un spécialiste

Broyeurs de branches - DL Workx

Par exemple, si nous indiquons une épaisseur maximale de 10 cm, vous pouvez mieux utiliser ce broyeur si la majorité des branches ne font pas plus de 6 à 8 cm d'épaisseur. Ensuite, vous décidez de l'entraînement de l'hélico. Vous opterez pour un moteur à essence, un moteur électrique ou une prise de force. Broyeur professionnel

Consulter un spécialiste

Revêtement de pierre Sable naturel 1000x60 cm Leroy Merlin

Fait de non-tissé PP polaire et de la colle sécuritaire pour l'eau potable, le revêtement de pierre de jardin est durable et présente un aspect naturel. ... polaire PP non tissée, colle sécuritaire pour l'eau potable Dimensions : 1000 x 60 cm (L x l) Épaisseur : 4,5 mm Couleur : sable naturel Matériau : polaire PP non tissée, colle ...

Consulter un spécialiste>> Next:équipement De Lusine De Préparation Utilisé Australie